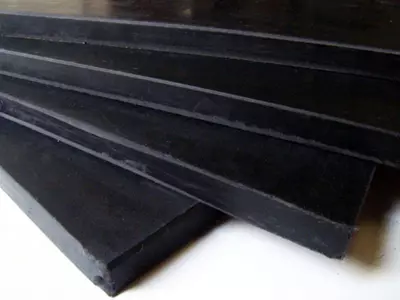

Dielectric Rubber

Specially formulated elastomer for a high insulation factor, it is used in subestation floors or in any application requiring a high dielectric strength value.

Black dielectric rubber is a material that insulates and prevents electric shocks and protects machinery from electrostatic discharges. This material is perfect for insulating electrically sensitive equipment, increasing the safety of the environment where it is installed.

Dielectric rubber in a high quality rubber floor, designed to protect workers from electric shock in high voltage equipment and switchboard areas. It is slip resistant, prevents slipping and provides maximum safety.

Physical and chemical properties: Dielectric Rubber

- Shore “A” hardness: 62-68

- Tensile strength, minimal: 550 PSI

- Elongation, minimal: 600 %

- Temperature Range: -13°F a 266°F

- Oils: Bad

- Acids: Medium

- Outdoors: Excellent

- Abrasion: Medium

Product Dimensions

- Plate: 3'3" x 3'3", 1/16" to 3" thickness

- Sheets: 3'3" x 32'9 " long, with 1/16" to 5/16" thickness

- Sheets: 3'3" wide x 16'4" long, with 3/8" to 5/8" thickness

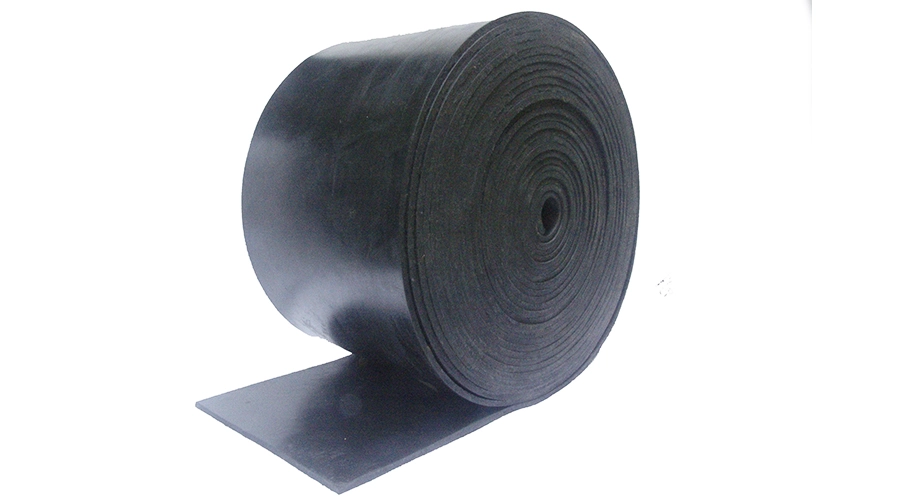

Rubber Antistatic

Our anti-static rubber, through a controlled conductivity, lets you download all types ofground static charges, thus, is ideal for assembly lines and integrated circuits that handle all types of chips which is not supported by static electricity.

Our antistatic rubber flooring, through controlled conductivity, allows all types of static charges to be discharged to ground.

Physical and chemical properties: Rubber Antistatic

- Shore “A” hardness: 60-65

- Tensile strength, minimal: 1000 PSI

- Elongation, minimal: 400 %

- Temperature Range: -13°F a 221°F

- Oils: Good

- Acids: Medium

- Outdoors: Medium

- Abrasion: Good

We manufacture this magnificent antistatic roll to cover any area that needs to isolate from the small current spikes that go through the human body to other bodies with different charges.

Product Dimensions

- Plate: 3'3" x 3'3", 1/16" to 1" thickness

- Sheets: 3'3" x 32'9 " long, with 1/16" to 5/16" thickness

Antistatic rubber flooring in roll and plate, always useful for workshops involving sensitive electronic equipment, is an ideal solution to prevent electrical devices from being damaged by discharges that directly affect various electronic components and circuits.

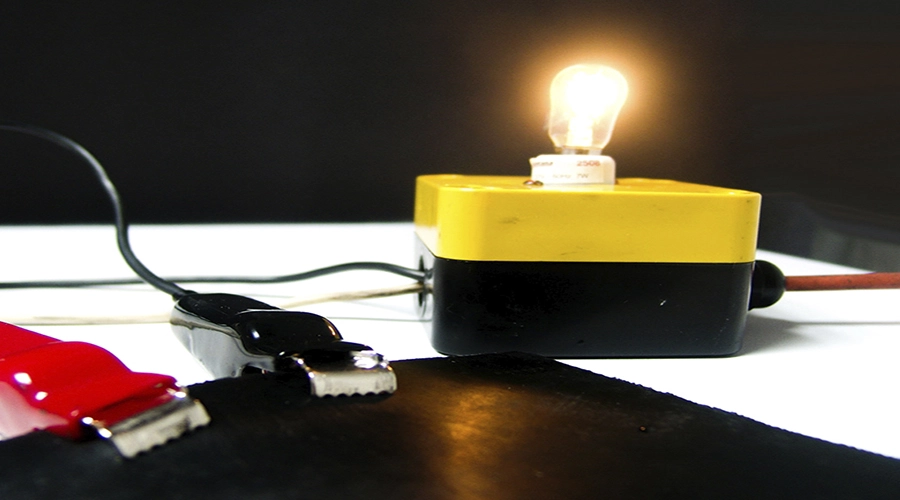

Conductive Rubber

Our anti-static rubber, through a controlled conductivity, lets you download all types ofground static charges, thus, is ideal for assembly lines and integrated circuits that handle all types of chips which is not supported by static electricity.

Our electrically conductive rubber is capable of transmitting electricity. Therefore, its electrical behavior makes it suitable for medical treatments.

Physical and chemical properties: Conductive Rubber

- Shore “A” hardness: 70-80

- Tensile strength, minimal: 1250 PSI

- Elongation, minimal: 350 %

- Temperature Range: -13°F a 221°F

- Oils: Good

- Acids: Medium

- Outdoors: Medium

- Abrasion: Good

Product Dimensions

- Plate: 3'3" x 3'3", 1/16" to 1" thickness

- Sheets: 3'3" x 32'9 " long, with 1/16" to 5/16" thickness

Electrically conductive rubber can transmit electricity. Due to its electrical behavior, it is suitable for medical treatments where the application of electric current to the human body must be dosed. In addition to special industrial applications, such as safety in areas where explosive materials and activities with static charges are handled.